MetraSCAN 3D

ULTIMATE ACCURACY & FLEXIBILITY

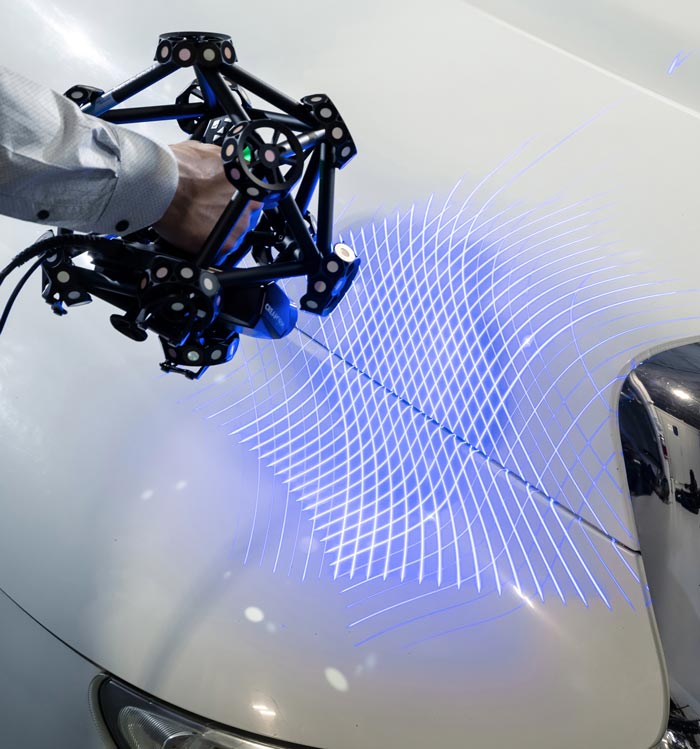

The MetraSCAN 3D optical CMM scanner line-up is specifically designed for manufacturing and metrology professionals who do not want to compromise on quality or efficiency. It can withstand any production environment, including shop floor vibrations, part movements and environmental instability – all while accelerating 3D measurement workflows. This optical CMM scanner has been engineered to perform highly accurate and repeatable metrology-grade measurements and 3D geometrical surface inspections.

Speed and accuracy combined with versatility

When paired with the HandyPROBE, Creaform’s handheld optical coordinate measuring machine (PCMM) with probing capabilities, users can also harness the power of both 3D scanning and probing for complete, end-to-end inspection processes.

Accuracy of 0.025mm

ISO 17025

Large Scanning Area

Scan-to-Mesh in seconds

Patented Technology

Get the ultimate portable metrology-grade 3D scanner for product development and quality control.

Learn how the MetraSCAN 3D can accelerate your time to market and mitigate costly quality control issues.

Faster 3D scanning

The MetraSCAN 3D features 15 laser crosses and a high measurement rate to accelerate 3D scanning processes. Thanks to quick setup and onboarding, real-time scans and ready-to-use files, your 3D scanning workflow will never have been faster.

• High measurement rate

1,800,000 measurements/second

• Large scanning area for all types of parts

15 laser crosses

• Ultra-quick setup

No warm-up time; users can be up-and-running in less than 5 minutes

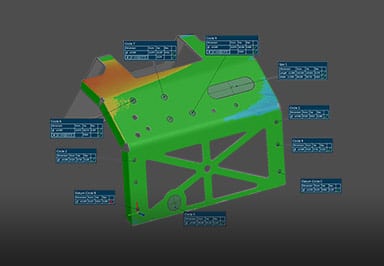

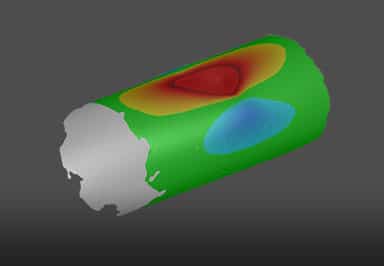

Impressive shop floor accuracy

Free from any rigid measurement setup requirements, the MetraSCAN 3D is designed specifically for use on shop floors. It delivers accurate results, regardless of the measurement setup quality and user experience level. Thanks to the C-TrackTM optical tracker that enables dynamic referencing, the scanner, the part and the optical tracker can move during inspection and still provide accurate measurements.

0.025 mm

• Volumetric Accuracy

0.064 mm

• Reliable Acceptance Tests

Based on VDI/VDE 2634 Part 3 standard ISO 17025 accredited laboratory

• Shop floor accuracy with dynamic referencing

Measurement accuracy insensitive to environmental instabilities

• High resolution

Measures all types of complex and highly detailed parts

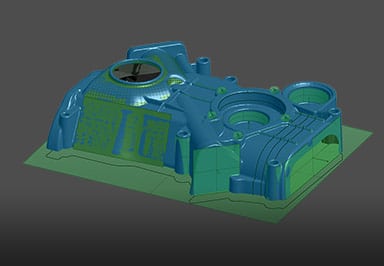

Unmatched versatility

Highly versatile, the MetraSCAN 3D can be used to scan various part sizes and surface finishes in real time—all with the same device.

With its extendable measurement volume, parts of any shape, complexity, and geometry can be measured easily without loss in accuracy or requiring leapfrog.

Ideal for shiny and reflective surfaces

• Large and easily extendable measurement volume

Wider than other portable CMMs No leapfrog required

• Reliable Acceptance Tests

Based on VDI/VDE 2634 Part 3 standard ISO 17025 accredited laboratory

• Optional HandyPROBE

Combination of both 3D scanning and probing No targets required

Technical Specifications

Accuracy

0.025mm

Volumetric Accuracy

0.064mm

Measurement Resolution

0.025mm

Measurement Resolution

1,800,000 measurements/s

Part Size Range

0.2 – 6m

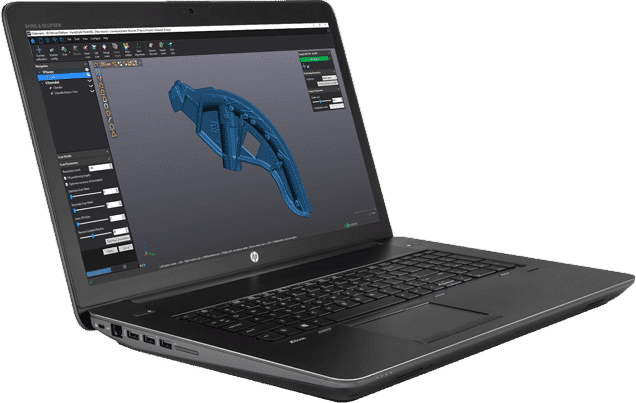

MetraSCAN 3D Software

The MetraSCAN 3D comes with VXelements, which powers our entire suite of 3D scanning and measurement technologies. It combines all the essential tools you need from data acquisition to CAD Software, in a user-friendly, simplified and sleek working environment.

Software Modules

Compatible Software

Get the ultimate portable metrology-grade 3D scanner for product development and quality control.

Learn how the MetraSCAN 3D can accelerate your time to market and mitigate costly quality control issues.